We are in the news!

Los Angeles, CA. July 23, 2020 — MEM Doubles Factory. Modular Elevator Manufacturing (MEM) has now doubled its production facility. This is in response to a significant increase in sales growth as a result of a new nationwide marketing and sales campaign. Interest in the high-quality commercial modular elevator product is way up due to the national strategy being employed since the beginning of 2020 and the uniqueness of the product itself. MEM elevators are now scheduled to ship from the Los Angeles based company to as far away as New York City and projects are being considered at all points in between.

This dramatic growth in the modular elevator market is despite the outbreak of the Covid-19 virus for many reasons. First, modular elevators set in less than a day. Then they are started up in less than a week in most cases. That means fewer people coming and going from the construction job-site, potentially meaning less spread. This contrasts with the old way elevators have been built. That method requires a steady stream of workers showing up for months at a time and working closely together.

With conventional elevators, a hoistway is constructed first, and then all the components are shipped to the job-site and installed. This can be a painstaking and dangerous process as it all takes place in a cramped hoistway. Now with social distancing a concern, the troop of elevator mechanics, construction workers and helpers required for the conventional method may mean a higher risk for spread.

Second, the modular elevator is manufactured in a controlled environment. Safety protocols can be employed easily That is not the case at most project sites. Social distancing and sanitizing the work area can be easily managed. An additional plus of the factory controlled environment is that there is increased elevator and hoistway quality. The manufactured hoistway is a tough steel frame, sheathed in drywall. All of the elevator components are already installed in a controlled environment. They arrive at the project location, are craned into place, and then started up when power is available.

Lastly, project completion overall is much faster when modular is used. It takes the elevator off the critical path during construction. The job can be completed faster leading to a safer building environment.

All of the benefits makes the sales process more of an education than a high-pressure sales pitch. According to Vice President of Sales, Hugo Beltran “The product is perfect for the times in which we are living. They are high-quality commercial elevators set and started up faster than conventional elevators. This means fewer people at the job-site. That makes modular elevators from MEM greener, safer and smarter.”

He went on to say that education on the benefits is made easier due to the competitive pricing. “We are being selected as the elevator solution by our clients because of the investment. It is a better manufactured, higher quality product in line with general elevator pricing and the hoistway is included.”

At the newly enlarged production facility MEM produces elevators from simple ADA compliant models to freight elevators. They are routinely sold for several types of buildings including educational, hospitality, healthcare, multi-family, commercial, storage and parking structures. For more information on MEM go to at modualrelevator.com. See the article MEM Doubles Factory here.

I usually spend hours, if not days, uncovering research about elevators and looking for interesting and useful facts and figures to post in my blog. I research, work and write several times a month hoping to enlighten the reader and maybe make you think or at least smile. I really like doing that because I know elevators are a very interesting subject; so simple yet complex and full of fun details that fascinate.

Also, those in the elevator industry love to gather information and pass it on so I have a great, knowledgeable audience. This combination of smart people and facts can lead to new perspectives or different ways of thinking about the largest moving object in a building.

I also love uncovering the history of elevators, the modular business, construction and manufacturing as subject matter or as a springboard into the elevator industry. But, every once in a while someone does it a little bit better than I do. So rather than trying to copy what was done, it would be better to just post it as is. Below is one such example of a short, concise history that is better than I could have cobbled together.

You can quibble with some of the details if you are in an argumentative mood or choose to believe the romanticized version of the Otis legend, but on the whole this video, although abbreviated, is well researched and correct. The History Guy does a great job in all the videos he produces and I would recommend you poke around a bit on his YouTube page after you watch the video about your favorite mode of vertical transportation. You will find something that interests you for sure.

The video is informative and the format is designed for a broad audience so it is kept short, and as a result the History Guy did not have the time to get in depth about the future of vertical transportation. And as we all know for any low or mid-rise building modular elevators are the future.

If you want more information on that or would like to see one placed you can watch our YouTube video too. Really a fully installed elevator in a couple of hours???? Absolutely true and astounding to see.

Of course for more info you can click the button below and get a Fast Track quote on how much a modular unit would be for your next project. You can also contact us any time for information about MEM or modular elevators.

We have a pretty interesting history too…”A history that deserves to be remembered!”

Stadium Chooses Modular Elevator – Elevators are a crucial part of any stadium and part of any good stadium design. Depending on the size, layout and capacity of the venue, anywhere from one to ten elevators or more may be needed. The purpose of the stadium elevator is to provide everyone unencumbered access, assist with foot traffic concerns and to meet American Disabilities Act (ADA) compliance. For instance the renovation to the venerable Dodger Stadium this past year added five new elevators to the existing two, significantly increasing accessibility.

To ensure access, elevators continue to be the best solution for vertical transportation needs. However, that solution comes with a myriad of problems when a project is in the construction phase if traditional or conventional elevators are utilized.

To alleviate problems with the elevator hoistway construction, component installation and then start up and adjustment the better alternative is a modular elevator. It is a conventional elevator built and installed in an unconventional way and it is the best alternative for any mid or low rise project. Instead of a cumbersome three-phase process where the shaft is built first, elevator is assembled inside second, and then it is turned on and adjusted, the first two steps are done completely in a factory. The elevator arrives as a finished product ready to be placed by a crane.

Most stadium elevators fall into the low and mid rise category, modular (like the one pictured) is the perfect solution.

The unique manufacturing process makes modular a better alternative for the following reasons:

In the stadium project shown, the modular elevator demonstrates its flexibility by being placed in an open area left specifically for the elevator. That was the best choice in this situation, however the modular elevator can be placed at anytime in the building process. Sometimes it get placed first and then built around. Other times it is the last piece of the building puzzle. We will help you decide what is best for your particular project.

Modular elevators can also be placed next to an existing structure or stadium grandstands or inside a building depending on the need. One of the most popular uses regarding stadiums is to retrofit our elevator to gain access to a press box or higher level of seating. However, as pictured modular is perfect for new stadium construction as well.

Practically there is no other alternative for stadiums other than to have elevators installed for access and compliance. So why not use a proven system that alleviates so many of the headaches associated with elevators in construction projects.

If you have a stadium or other building that needs a quality, commercial elevator just click the button below for a Fast Track budget number and find out like our other partners that we are quality elevators taking you to a higher level.

Modular – Affordable Housing Solution – In the United States there is currently an affordable housing crisis. With the current virus, it is easy to forget the need. However, it is estimated that we as a nation are at a minimum 7.2 million housing units short. That number could be much higher according to the National Low Income Housing Coalition. The result is any means that could shorten the build time should be considered. Easing the burden on the affordable housing construction industry would be welcomed.

Modular elevators are designed specifically to be an easy, fast, quality solution that many in the affordable housing sector are now looking for to meet the growing nationwide need. A reputable nationwide modular elevator company is needed.

This was the case recently regarding a 51-unit housing project in San Ysidro, an area of San Diego, California. Modular Elevator Manufacturing (MEM) was able to provide a quality elevator for the project and improve efficiency of the construction process. The affordable housing was needed and MEM helped with that need.

Patrick Meredith, Vice President of Construction at National Core, the developer, general contractor, property manager and primary catalyst for the project, decided to go with a modular elevator solution due to the benefits. He was excited to see the modular elevator craned into place and said, “The design of this project fit the modular elevator extremely well and we look forward to doing future projects with MEM.”

The San Ysidro project is a senior village with the purpose of increasing housing space in the San Diego area. But, this type of project is just one kind of various developments that National Core completes nationwide. They are a non-profit affordable housing developer, but their mission goes well beyond senior living and bricks and mortar. Family housing is also an important part of their mission and they strive to provide a community with improve neighborhood stability.

Also, through caring long-term management and maintenance they provide more than a place for families and seniors to live. They go as far as providing industry-leading services such as senior wellness, preschool and after school programs.

Regarding the San Ysidro project using a modular elevator, it is easy to see the benefits of the efficiency and time savings in this time-lapse video. Note that over half of the time-lapse is site preparation. What you do not see is that while the prep and foundation work for the site was being conducted, the high-quality modular elevator was being produced in the MEM factory.

When the site work was prepped and done and National Core wanted the elevator it was shipped on a truck and put placed in less than a day. The uniqueness of modular unit is that the simple looking hoistway in the video contains all of the elevator components pre-installed inside. Everything from the car, to the rails, doors and wiring are already done. This allows for smooth installation and faster project completion.

Meredith is convinced that modular is a wise consideration for the housing crunch saying that, “It was good to have everything dialed in.” regarding the elevator and in projects like San Ysidro “It was a perfect fit.”

If you are looking for a great alternative that can improve efficiency for your project, contact us or click the button below if you have a project in mind. We are more than happy to provide you with a Fast Track budget number in less that 24 hours. Whether you are in the affordable housing industry or any other, modular elevators are the best alternative for 10 stories or below.

Modular – Affordable Housing Solution – In the United States there is currently an affordable housing crisis. With the current virus, it is easy to forget the need. However, it is estimated that we as a nation are at a minimum 7.2 million housing units short. That number could be much higher according to the National Low Income Housing Coalition. The result is any means that could shorten the build time should be considered. Easing the burden on the affordable housing construction industry would be welcomed.

Modular elevators are designed specifically to be an easy, fast, quality solution that many in the affordable housing sector are now looking for to meet the growing nationwide need. A reputable nationwide modular elevator company is needed.

This was the case recently regarding a 51-unit housing project in San Ysidro, an area of San Diego, California. Modular Elevator Manufacturing (MEM) was able to provide a quality elevator for the project and improve efficiency of the construction process. The affordable housing was needed and MEM helped with that need.

Patrick Meredith, Vice President of Construction at National Core, the developer, general contractor, property manager and primary catalyst for the project, decided to go with a modular elevator solution due to the benefits. He was excited to see the modular elevator craned into place and said, “The design of this project fit the modular elevator extremely well and we look forward to doing future projects with MEM.”

The San Ysidro project is a senior village with the purpose of increasing housing space in the San Diego area. But, this type of project is just one kind of various developments that National Core completes nationwide. They are a non-profit affordable housing developer, but their mission goes well beyond senior living and bricks and mortar. Family housing is also an important part of their mission and they strive to provide a community with improve neighborhood stability.

Also, through caring long-term management and maintenance they provide more than a place for families and seniors to live. They go as far as providing industry-leading services such as senior wellness, preschool and after school programs.

Regarding the San Ysidro project using a modular elevator, it is easy to see the benefits of the efficiency and time savings in this time-lapse video. Note that over half of the time-lapse is site preparation. What you do not see is that while the prep and foundation work for the site was being conducted, the high-quality modular elevator was being produced in the MEM factory.

When the site work was prepped and done and National Core wanted the elevator it was shipped on a truck and put placed in less than a day. The uniqueness of modular unit is that the simple looking hoistway in the video contains all of the elevator components pre-installed inside. Everything from the car, to the rails, doors and wiring are already done. This allows for smooth installation and faster project completion.

Meredith is convinced that modular is a wise consideration for the housing crunch saying that, “It was good to have everything dialed in.” regarding the elevator and in projects like San Ysidro “It was a perfect fit.”

If you are looking for a great alternative that can improve efficiency for your project, contact us or click the button below if you have a project in mind. We are more than happy to provide you with a Fast Track budget number in less that 24 hours. Whether you are in the affordable housing industry or any other, modular elevators are the best alternative for 10 stories or below.

“The elevator holds everything up!” that is a common complaint among those in the modular building industry. Modular companies are growing by leaps and bounds. However, finding a way to incorporate vertical transportation quickly and smoothly was always a sticking point.

It is true that modular building is the future. It just makes sense as it means a high-quality project completed in a greener and safer way. But one of the biggest selling points with modular is the speed in which the project can be completed. Typically when you place traditional construction on a timeline there are gaps. After the permits and financing is set, the ground has to be prepped. Then the foundation is poured and infrastructure for the building brought in. Months tick by.

Meanwhile, despite the project being totally ready to go, the building makes it no further. There it sits as plans on a drawing board until the site is completely ready. Modular takes all of the waiting out of the process. The building can begin as the site is being prepped. In that way when the location is ready, modular units are ready to be immediately swung into place. It is estimated that modular building can reduce time significantly. This is because construction of the modular components can occur simultaneously with the site and foundation work. This means projects can be completed 30% to 50% sooner than traditional construction.

The modular process does speed things up incredibly fast, but there has been a huge fly in the ointment. The elevator. Despite advances in modular building, the elevator was mired in old-fashioned construction practices. Or the companies that built modular elevators were so low in quality that headaches outweighed any benefits of speed. Dangerous product were even being distributed. A new nationwide solution had to be created for the modular industry.

The results is MEM and we are increasing distribution to the whole nation. Now from New York to California and Florida to Alaska there is a true quality solution. A solution that is reliable and fast to set and start up.

As an example, realizing the need for speed and quality, MEM was called on a multi-family housing unit. It was completed on time and on budget with quality elevators. The builder’s experience had dictated that a conventional elevator NEVER gets the elevator done on time. But, they called MEM and got a taste of what we can do. Now they will never go back to any other way.

Soon modular builders will start using MEM nationwide and the complaint about the elevator holding up the project will disappear. It will be just like the solution we provided above and there will be no turning back from the quality and speed we provide.

If you have a project in mind and you are ready to try out a modular elevator, click the link below and we can give you budget numbers in a day. To fill out the Fast Track quote we just need a little simple information to get you started on a fast – safe – quality solution.

Modular Elevator Manufacturing (MEM) is now distributing their high-quality modular elevators nationwide and as a result have doubled their factory floor space.

As the demand for a high-quality modular elevators has increased MEM is ready to meet that demand with a nationwide roll out of their products. Whether for schools, commercial space, hospitality, medical facilities, multi-family units or parking structures MEM can now meet the demand from the east coast to the west coast.

The key to the increased growth of MEM and new distribution effort is their desire to provide high-quality modular elevators as an alternative to traditionally build elevators. MEM President – Tom Shield is proud of the accomplishment and business milestone, “After 40 years in the construction business and over 20 years in the elevator manufacturing industry, it was time to allow our product to be sold and installed nationwide. We have a great team that knows elevators inside out and the consistent quality we provide has made this growth possible.”

He went on to say, “It is my philosophy that good business is quality business. We do everything that we can to mitigate drama, and low quality and high drama go hand in hand. As an example of safety our EMR rating is .75, which is excellent.”

Because of the continued, steady growth MEM has acquired additional manufacturing space. The factory floor now has twice the capacity of the already successful business. The expansion allows for improvements in the manufacturing process and allows the placement of more jobs inline for completion. It is a huge expansion that MEM is ready for according to Shield, “If you are looking for a better elevator alternative and would like to consider a high-quality modular unit for mid and low-rise projects; we are ready. Our team will answer any questions and provide a Fast Track budget number in hours or over the phone if you call in. We are excited about the new factory floor space and the growth to nationwide distribution.”

The modular concept for elevators is revolutionary and MEM is one of the pioneers that saw the need for safety, quality and fast set and start up. To summarize the difference between modular and stick-built you should know that they are simply conventional elevators, just unconventionally delivered and installed. Modular elevators are the hoistway, built with tough 4X4 inch HHS (Hollow Structural Steel), wrapped in mold resistant drywall to your specification with all the elevator components already inside. That means when they arrive at the site the wiring, cab, rails and other components are already inside the structure. It is then placed with a crane at the job-site in the elevator pit in less than a day and then can be started up in less than a week. This means that it takes the elevator off the critical path saving time, headaches and hassles.

Modular elevators are also extremely flexible in use and can be included in retrofit projects, modular projects or new traditional construction. Generally any time you would use a conventional elevator, a modular can be used in its place.

Lastly, when it comes to design, MEM elevators inside the cab and on the exterior of the hoistway can carry any look or feel. Architects are impressed with their flexibility. If you would like a budget number and be a part of MEM growth on a project you currently are considering, click the button below to get the process started.

When we say fastest installing elevator, that is exactly what we mean. Even 6-stop elevators can be set in a day. Often they are manufactured in stack-able sections that can be placed when the project calls for it.

When you use the fastest installing elevator for your project you are no longer hostage to the elevator and elevator industry. The elevator is a complete package consisting of the hoistway and all of the components already manufactured inside. It is placed when convenient to you and your team. This can lead to a reduced build timeline and cost savings.

Check out how you can get this elevator for your next project. Click Here!

Unique and functional – That is what the architect for this job wanted. They found the best alternative to provide the solution was MEM. We are where you find high-quality modular elevators. They set up in a day and install in a week or less. With all the components already inside.

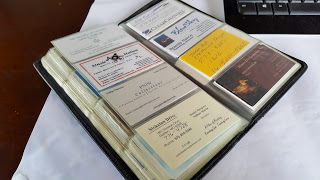

My Monday morning observation when deep cleaning points to modular and modular elevators. When going through my desk in what should be an annual ritual, but too often neglected, I ran across an interesting item. Buried amongst the broke watches, a plethora of wires that go to who knows what devises and batteries (none of which still held a charge), I found a true vestige of the past; the old business card folder.

I remember wanting one when I first graduated from college as it was considered a true and genuine indicator that you were in business, much like the now rare, rigid leather briefcase. The folder was unique as it was a single place to put all of your valuable leads and contacts. It was one step above the old Rolodex as it was leather bound and portable.

I paged through the clear plastic sleeves of cards chuckling over the graphic design style of the various rectangles of 100% rag, 16 point stock that populated the folder. Each was a prized bundle of information I had collected over time and was once held dear, like a Stan Musial baseball card, but now I noticed how few were even still relevant. Businesses had closed or changed names, people had long since moved on or the information was out of date with AOL email addresses and FAX numbers prominently displayed.

But the cards, yellowed with time, were not the funniest part of what I discovered from my perspective. It is the very notion of keeping a catalog of cards categorized based on business type and then alphabetized all in a literal folder. The time for that kind of system has declined to the point of uselessness, worth little more than short lived amusement. That is why, despite a couple decades of usefulness, it found itself shoved to the rear of an over-packed desk drawer.

A better system for keeping track of people and business connections has emerged and in honesty leaves the old folder in the dust and ultimately in the circular file.

I have seen that change too in the elevator industry. There was a time not so long ago that the big elevator companies held a universal monopoly and if you were going to construct a low or mid-rise building you had to pay homage, live within their timelines and buy what they were selling. Thank goodness the old stick-built alternative is due for the dustbin of history just like my old business card folder.

Now if you want a high-quality commercial elevator you simply have to call MEM or email them for FastTrack numbers. Once you place your order you can break away from the control of the elevator industry for good. They no longer can dictate what you can do on your job site, building project or pocketbook. You will be free to schedule elevator work when you want it done, not the other way around. Free to choose who you want the elevator maintenance company to be with a fair contract, not one laced with automatic increases and non-proprietary parts. Deep cleaning indeed.

The barnacle encrusted elevator industry is and will fight back, but the march of time is lined up against them and ultimately modular will be the first and best choice for everyone. Not because it is new (it has been around for a couple decades now), but because it is a better solution. Faster, smarter, greener and can be less expensive.

That can all be said because building a hoistway in a factory, out of the elements and off site means higher quality, truer construction and no delays. Then putting all of the elevator components in the the hoistway while it is horizontal means no safety concerns of lifting heavy parts. The wiring goes faster and the cab is built to more exacting specifications. Just better.

So engage in a little deep cleaning and clean out your desk of all those old drawings, plans and specifications and get ready for the future with modular elevators.

| Thank you for Signing Up |