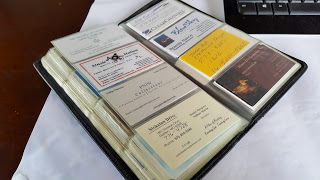

My Monday morning observation when deep cleaning points to modular and modular elevators. When going through my desk in what should be an annual ritual, but too often neglected, I ran across an interesting item. Buried amongst the broke watches, a plethora of wires that go to who knows what devises and batteries (none of which still held a charge), I found a true vestige of the past; the old business card folder.

I remember wanting one when I first graduated from college as it was considered a true and genuine indicator that you were in business, much like the now rare, rigid leather briefcase. The folder was unique as it was a single place to put all of your valuable leads and contacts. It was one step above the old Rolodex as it was leather bound and portable.

I paged through the clear plastic sleeves of cards chuckling over the graphic design style of the various rectangles of 100% rag, 16 point stock that populated the folder. Each was a prized bundle of information I had collected over time and was once held dear, like a Stan Musial baseball card, but now I noticed how few were even still relevant. Businesses had closed or changed names, people had long since moved on or the information was out of date with AOL email addresses and FAX numbers prominently displayed.

But the cards, yellowed with time, were not the funniest part of what I discovered from my perspective. It is the very notion of keeping a catalog of cards categorized based on business type and then alphabetized all in a literal folder. The time for that kind of system has declined to the point of uselessness, worth little more than short lived amusement. That is why, despite a couple decades of usefulness, it found itself shoved to the rear of an over-packed desk drawer.

A better system for keeping track of people and business connections has emerged and in honesty leaves the old folder in the dust and ultimately in the circular file.

I have seen that change too in the elevator industry. There was a time not so long ago that the big elevator companies held a universal monopoly and if you were going to construct a low or mid-rise building you had to pay homage, live within their timelines and buy what they were selling. Thank goodness the old stick-built alternative is due for the dustbin of history just like my old business card folder.

Now if you want a high-quality commercial elevator you simply have to call MEM or email them for FastTrack numbers. Once you place your order you can break away from the control of the elevator industry for good. They no longer can dictate what you can do on your job site, building project or pocketbook. You will be free to schedule elevator work when you want it done, not the other way around. Free to choose who you want the elevator maintenance company to be with a fair contract, not one laced with automatic increases and non-proprietary parts. Deep cleaning indeed.

The barnacle encrusted elevator industry is and will fight back, but the march of time is lined up against them and ultimately modular will be the first and best choice for everyone. Not because it is new (it has been around for a couple decades now), but because it is a better solution. Faster, smarter, greener and can be less expensive.

That can all be said because building a hoistway in a factory, out of the elements and off site means higher quality, truer construction and no delays. Then putting all of the elevator components in the the hoistway while it is horizontal means no safety concerns of lifting heavy parts. The wiring goes faster and the cab is built to more exacting specifications. Just better.

So engage in a little deep cleaning and clean out your desk of all those old drawings, plans and specifications and get ready for the future with modular elevators.

Elevator Speeds – Everyone wants faster. Many especially are obsessed with a faster car, but that is just the tip of the iceberg. Faster cars. Faster computers. Faster internet. But it really doesn’t work that way with elevators. For most low to mid-rise applications only 100 (for low) to 200 (for mid-rise) feet per minute (fpm) is desirable and for good reason. Any speed above 200 fpm would most likely never be hit in most applications due to stops and starts. So wanting more speed would be just a waste.

To explain further, higher elevator speeds in most hydraulic elevators are never obtained because elevators do not launch like rockets and have to stop in relatively short distances. The rate the elevator takes off at is called the jerk rate (please insert joke here) and how fast it reaches top speed is called acceleration. Acceleration and Jerk (rate of change of acceleration) are human comfort considerations that must be taken into account when looking at elevator speed. The practical limits (for math geeks) are 4 ft/sec^2 acceleration and 8 ft/sec^3 for jerk. If you are a math nerd, or you’re wanting to test out your math skills, this is a good place to start. But take it from me, fastest speeds in most elevators are never reached.

Even at the regular rate of travel between 100 to 200 fpm if the elevator took off too fast the occupants would be thrown to the floor like a character in a Loonie Tunes cartoon. Well…maybe the cartoon is a bit of an exaggeration.

So then if this is pretty common knowledge in the elevator world, why are elevator companies like MEM (Modular Elevator Manufacturing) asked to quote unbelievable rates of travel for even two-story buildings, sometimes five-times the proper speed? Two reasons. One is an honest oversight and the other seemingly more insidious.

Let’s look at honest reasons first. Completed project specifications or spec sheets are filled with tons of information. Like the Dictionary of Architecture & Construction says a specification sheet is, “a written document describing in detail the scope of work, materials to be used, methods of installation, and quality of workmanship for a parcel of work to be placed under contract; usually utilized in conjunction with working (contract) drawings in building construction.” That is a lot of information that has to be captured, updated and controlled.

So when it comes to any building project it is a mammoth effort and elevators are often held separately with elevator providers pulling the info together to be inserted. That means that there is sometimes a lack of direct oversight early in the process regarding the elevator. Also, the desired specs out of need and convenience have been largely copied and pasted from another source.

The other honest mistake is when a company has had several projects of similar height or elevator travel. They feel the specifications can simply be copied and reused. Changes and updates are always meant to be completed, but sometimes the elevator speeds are missed and one or two floors of travel can mean significant changes. These kinds of “whoops” can happen, but the mistake is usually caught somewhere in the process. Countless times we have had to get clarification when the overall speed does not align with the project. We call and the correction is made.

Now for the more insidious reason aspects of specifications are way out of whack regarding elevator speeds. Sometimes when asked for information on pricing, big elevator companies use the opportunity to push certain products and features; right now they are currently promoting traction rather than hydraulic elevators.

A more cynical perspective is that over the long-haul the maintenance of a traction unit is twice to three times more costly and therefore more profitable for them. This can lead to big elevator companies suggesting products that absolutely make no sense. I have personally had conversations with multiple building owners and project managers of two and three-story building projects that were sold on the idea they needed a traction unit for more speed. In reality they needed no more than a simple hydraulic elevator with 200 fpm travel speed. The initial investment of going hydraulic is less and so are the legacy costs of maintenance.

Keep in mind at MEM we produce all types of elevators, so we are not pushing one over another, we just want to make sure that the elevator matches the project. So I guess my old Latin teacher was right “Caveat emptor” ~ Buyer beware. It is as true today as when it was first uttered.

If speed is still a concern, but you are thinking more about the speed of the overall construction process there is only one real choice in elevator that can move your along faster and that is a modular elevator from MEM. Contact Hugo Beltran at hbeltran@tlshield.com or call him at 800-755-9359. He would be glad to talk to you about the speed of elevators. For more research on modular elevators click here for our website.

| Thank you for Signing Up |