Non-proprietary parts matter. However, often times non-proprietary parts are over looked, not considered or just not understood. So, let’s start from the beginning. What’s the definition of non-proprietary elevator parts and how can they solve problems regarding your elevator choice.

Generally, proprietary elevator parts are components produced, marketed and controlled under exclusive legal rights of the manufacturer. The manufacturer has no obligation to share any information about the part or component, how it functions, how it operates, how it can be repaired or used to adjust or improve the overall functioning of an elevator unless it is contractually obligated to do so.

Non-proprietary on the other hand, means there are no restrictions to the use or what company can repair or improve the functionality of the elevator.

Well that was a mouthful. The definition can be reduced to a more simple, proprietary elevator parts are ones that only the manufacturer can repair or use in a repair or maintenance of an elevator. Non-proprietary opens the door to any qualified and licensed elevator professional.

An even more concise characterization is, proprietary bad; non-proprietary good.

But why? Why are proprietary parts to be avoided when looking at elevator purchases.

There are limited arguments against choosing an elevator that has non-proprietary parts over proprietary. When non-proprietary options were first available, there was a short time that they were considered inferior due to their recent emergence.

That thinking is no longer a concern. There is a decades long track record now that shows reliability and durability for non-proprietary components. Keep in mind that all elevator components and elevator operations are subject to elevator codes, inspections, and parts must pass rigorous testing before they would ever be allowed in an elevator.

Also, much of the functionality that proprietary elevators could boast of is now available with non-proprietary units.

Too many times we receive calls from individuals that are dissatisfied with their current maintenance supplier. They are sometimes unresponsive, operate at their own pace with little concern for the end user or the building owner and often lack availability of parts or tools with many on back order. With proprietary parts you lose the ability to find solutions to the problems you are facing.

This was illustrated in a recent article regarding elevator repair delays. A lack of parts was the cause for denying people mobility and access. You can help shorten that time of repair if you chose for your next project an elevator without proprietary parts. If you want to know more about us, just click one of the buttons below. We would love to talk to you about your next elevator project.

You should care – Elevator parts are not all equal…but they are. Years ago there used to be a commercial that had the catch phrase “Parts is parts”. They were talking about chicken nuggets and not vertical transportation and their facetious point was parts are not all equal. There are better and worse pieces of the chicken to use in the production of a nugget.

In the home or commercial elevator industry that knife cuts both ways and a bit hard to explain. First, it is true there are differences company to company in components. But second, those differences are superficial at best and for a purpose. So the parts are not all equal but… still equal??? How does that work?

That doesn’t seem to make sense so let me explain this weird dichotomy by stating the following. Factually, most companies purchase the bulk of their components from the same group of independent companies. As a result an elevator, home or commercial, is filled with dozens of components and pieces that come from those various companies from around the world. The difference is largely relegated to different nameplates and logos being etched or painted on the components themselves and that is about it.

This gives the illusion that they are all coming from the elevator company you are buying from. Generally that is not true. As a result when you step into an elevator car most often very little of what you see or that makes it go up and down, comes from the name on the control panel. And in all likelihood the bulk of those parts are found in every other elevator you ride regardless of the company.

Also, the vertical transportation industry, for good reason, is highly regulated. Elevators in the United States make 18 billion passenger trips per year according to the National Elevator Industry Inc. For that reason alone it is very important that all parts must meet high standards. You just can’t put anything you want in the elevator as a component. They must be test and approved for quality and durability.

Alright, if only a handful of companies produce most of elevator components and all parts meet the same rigorous standards, how can they possibly be different? Well before I get to that I want you to know that I am not wearing a tinfoil hat. I believe that we did go to the moon, Elvis is dead and aliens had no part in building the pyramids. So what I am about to say is not a crazy conspiracy.

Here, goes. The big commercial elevator companies make the bulk of their profits in maintenance and not selling you an elevator. Shocked? They realized pretty early on that if any certified elevator contractor could provide maintenance, they could lose customers and money. People would simply shop around and find the lowest price for service.

The solution was two-fold. First, sell elevators that require the most expensive maintenance agreements regardless of the purpose. Second, place in those elevators components from manufacturers that will require special tools, passwords or programs to maintain the elevator.

If you combine those two principles with a confiscatory maintenance agreement you have a lock on maintenance income for that unit for decades. And there is really no way for the building owner to extricate themselves from the long-term costs.

So, despite elevator components largely being the same, parts are not all equal. This is by design and for a specific purpose that has nothing to do with the elevator ride or functionality.

Unfortunately, when asked, “What can I do?” the responses are limited. This is especially if you already have an elevator in place. It is not practical nor cost effective to replace the proprietary parts that force you into the long-term contract. It’s like the old adage, you pay for some mistakes forever. But learning from those mistakes is important as well as spread the word that you can make upfront decisions next time that will save you from the headaches and costs associated with choosing the wrong company.

The word to commit to memory is non-proprietary. Non-proprietary parts and components are simply those that any elevator technician can work on. They are not better or worse they are just accessible for maintenance from any company. You can even use the big elevator companies if you wish. It just opens the door to anyone to repair or maintain the elevator. So always, always, always have an elevator installed with non-proprietary parts.

Finally if you have any questions regarding what proprietary parts and components can mean to your elevator project please contact us. At TL Shield and MEM we pride ourselves on giving honest answers to your questions about elevators, home or commercial.

All you have to do is click one of the buttons below to get started.

Just a reminder that TL Shield and Associates along with their sister company Modular Elevator Manufacturing will be at the upcoming CASH Conference.

Stop by Booth #419 to see our latest video and discuss solutions to your vertical transportation needs. We will be featuring our MEM Elevator System. It is a commercial quality elevator that is DSA approve and plan checked. This speeds up your building process and assures you will get high quality every time.

See you at the show!

If you have heard about the modular elevator revolution and want to know more you don’t have to be at the show. You can simply click the buttons below.

One of the buttons is to request a FAST TRACK QUOTE. It is the fastest and easiest way to get a thumbnail estimate based on your specific project. Just fill out some simple information and you will be good to go. We will contact you with particulars and general pricing.

The second button is to request a LIVE VIRTUAL TOUR. That’s right! We pull back the curtain and let you see how we produce the most advanced elevator innovation since Otis cut the rope to show off his breaking system. During the tour you can ask any questions you wish and we can have a discussion about your needs. So hope to hear from you soon.

TL Shield is know in the Southern California area as the best provider of home elevators, wheelchair lifts and stair lifts. But many people do not know that TL Shield installs Modular Elevators as well. As vertical transportation experts with over 25 years of experience they have teams of quality technicians that are ready to install nearly any option that moves you up and down.

This was seen in their latest quality modular elevator installation at Newhart Middle School/Mission Viejo, CA. TL Shield installed an innovative modular elevator to perfection. As you can see, the project looks great. It went in faster for the school with no disruption to classes and embracing their movement towards innovation in what they teach and how they teach it.

If you would like to see more about this project or others like it, just let us know. We will meet with you regardless of what type of vertical transportation you need. We are experts that are willing to help. You can also schedule an in person visit by completing the form below.

For more great photos of the project, visit our good friends at Miller Construction. Their team did a great job as well!

We need Supportive Housing Elevators Fast. Supportive housing is also referred to affordable housing or low income housing, but regardless of the name the need is more than evident. So, when it comes to housing the homeless, faster is better to address the issue. But also we must use the resources available in a timely fashion. Funds are being allocated to help right now. As an example the Los Angeles City Council has approved more than $51 million in financing for the construction of new affordable and permanent supportive housing developments.

But that funding can be slippery if not acted on quickly and the need could continue to go unaddressed if not used. The bottom line is that funds allocated need to result in actual building projects that are designed for housing the at risk population as quickly as possible.

And there is the problem. As everyone in the construction industry knows, a building does not pop up overnight, even when funding is approved and support is given. It takes plumbing, electric, foundation work, drawings, permits and approvals. Lastly, if over one story the project takes the slowest component of any build project, an elevator. But TLShield and Modular Elevator Manufacturing (MEM) has the solution.

Elevator Sales Executive – Christian Lahud from TLShield & Associates explains, “In traditional construction the elevator hoistway is built and sits until power is turned on at the end of the project. Then and only then elevator technicians show up. They come and go at their leisure, carrying in elevator parts and installing them one at a time until the elevator is running.” Lahud went on to say that, “The elevator and its mechanics are the first on the site and last to leave. Everything is slowed down including other trades that need the elevator installed to finish.”

The MEM Elevator System however is produced in a factory environment where a hoistway is constructed with steel. The structure is engineered to be strong enough to be self-supporting in most cases. Then all of the elevator components are installed in the hoistway in the factory.

Ultimately, when it is needed it is loaded on to a truck, shipped to the jobsite and set in place. In four hours you will have a fully installed, commercial quality elevator ready to be started up and used. It can also double as a construction elevator.

Lahud says this makes MEM perfect for the affordable housing market. “The MEM Elevator System is high-quality, but fast in setting and startup. It is a real solution where speed is of the essence to address a pressing need. No other elevator system is shipped and in place when the customer wants it.”

How do we know we are the solution? Over the decades of experience we have produced several elevators for supportive housing with just a couple of the most recent projects pictured. As you can see, whether a steel frame structure or modular structure involving storage containers, the MEM Elevator System is a perfect fit. We can be what you need regardless of the structure type. Right now due to the speed of modular construction and the immediacy of the problem there seems to be a high demand for modular structures. But another fast way to build housing is using an existing structure.

With that in mind, we are perfect for retrofit opportunities. The initial purpose of the modular elevators was to attach them quickly to exteriors of existing buildings to make them more accessible. We have grown from servicing just that market over the past 30 years, but we are still experts you can rely on if you have a retrofit project in mind.

Wrapping it all up the benefits are obvious:

It maybe time to explore the possibilities further regarding supportive housing elevators and see if the MEM Elevator System can meet your needs. You can click the button below for a Fast Track Quote for a project you currently are working on. However, if you want to explore it more, request a LIVE VIRTUAL TOUR. We would be happy to pull back the curtain and show you how we produce the industry’s most successful modular elevator solution.

6 Reasons Modular Quality Matters – We have all been frustrated by low quality. Items purchased in good faith sometimes seem to break before they come out of the box. Or once out of the box, they look or perform nothing like what was pictured or promised when we bought the item. Instead of being happy with the purchase, words like cheap and flimsy cross our lips, meaning that we have been had. The more expensive the item, the more remorse follows.

However, in the modular industry quality is high because we take an antiquated process where onsite construction is the norm and move it to a production facility. What was then built by various people, in various trades, in various conditions becomes an orchestrated symphony of production. Historically poor quality and high cost is moved to a factory where exact processes and standards can be measured and accomplished. The modular process takes various acts of individual quality to a habit of success. For instance, at the Modular Elevator Manufacturing (our commercial elevator supplier) facility, they produce hoistways that are always plumb and level. That is simply due to the factory processes that cannot be accomplished on the jobsite and it shows.

“Quality is not an act, it is a habit.”

Aristotle

As Aristotle said, “Quality is not an act, it is a habit.” And those habits are formalized into higher quality with modular manufacturing. In modular building you will never hear “close enough” or “I guess we will have to make it fit.” It is right every time, because the habits that produce quality are built in.

Unfortunately, there are outliers in some manufacturing facilities. Quality becomes just a slogan. If modular quality matters why do some not improve quality? Procedures are skipped, shoddy workmanship is allowed, new practices are slow to be adopted or worse continued tinkering and “problem solving” doesn’t allow for systems to work. In other words, if you have a team of problem solvers constantly changing the system in an unorganized fashion, the quality will undoubtedly suffer.

At TL Shield we use Modular Elevator Manufacturing for our modular elevators. They make sure changes to procedures are checked and double checked before becoming standard because modular quality matters. One person cannot just change something at a whim, even if it is generally a good idea. The procedure must likewise be changed with the whole team being aware of any alterations. That is where habits of quality are formed for the whole organization.

We agree with the Phil Crosby philosophy of quality and as a literal rocket scientist he knew a thing or two about it. He said, “Quality is the result of a carefully constructed cultural environment. It has to be the fabric of the organization, not part of the fabric.” Quality is not posters, or slogans or bright ideas that get used once and then forgotten.

For us quality is a top-down effort and philosophy emanating from senior leadership and permeating the organization at every level. That is true of Modular Elevator Manufacturing as well. Quality is crucial and should matter that much at every business. It does at Modular Elevator Manufacturing where they take quality seriously.

With that said here are the 6 reasons quality matters at MEM. There are probably more but these are some of theirs:

The entire premise of modular construction is that by instilling factory processes into the construction trade, the industry can produce a higher level of quality, faster and often at a reduced cost. That is what they do at MEM day in and day out. However, when slipshod practices and lack of experience infiltrate the market, quality declines. Then the premise of factory production being better comes under attack.

Whether due to ignorance, no experience or a desire to make a fast buck, when quality is ignored the reputation of the industry gets sullied. The result is a better process that produces a better product (safer, greener and faster) becomes more difficult for the consumer to accept. Who knows how many dollars, how much time and how much energy has been wasted. How many injuries could have been avoided? All due to a very small number of businesses that do not see quality as important.

That is why we do not think “close enough” is good enough. We know that low-quality has a cost to the industry, the customer and to safety. We strive for quality in all we do. Whether you need a multi-family unit elevator or one for a medical facility, an elevator for a retrofit project or new construction we provide a quality solution.

If you have tried other vertical transportation specialists in the past and found that the quality with modular elevator was not as promised, don’t give up. Instead give TL Shield a try. We live by the above list of 6 reasons that modular quality matters and so does MEM. You will not be sold a bill of goods for a fast buck, but instead you will find a partner providing quality you can count on.

If you have a project in mind just click the button below, we would love to consult with you and you can get you budget numbers in less than a day. Of course you can also call us anytime, and have a real conversation with an expert in the elevator industry. We are looking forward to talking to you.

An elevator installed on your schedule sounds impossible. However, “When would you like your elevator delivered?” is a question that more and more people are hearing.

Keep in mind we are not talking about crates of components and tools. Consequently, you won’t find them laying around to be cobbled together with our system. We are talking about an actual fully installed elevator and hoistway craned into place. It is not magic (although it is magical to watch), but a reality with the MEM elevator system.

The benefits are all made possible because the hoistway is manufactured. All of the components then are installed in an assembly line fashion. That includes all the wiring, doors, elevator components and hall calls.

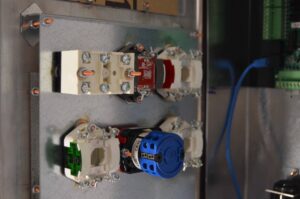

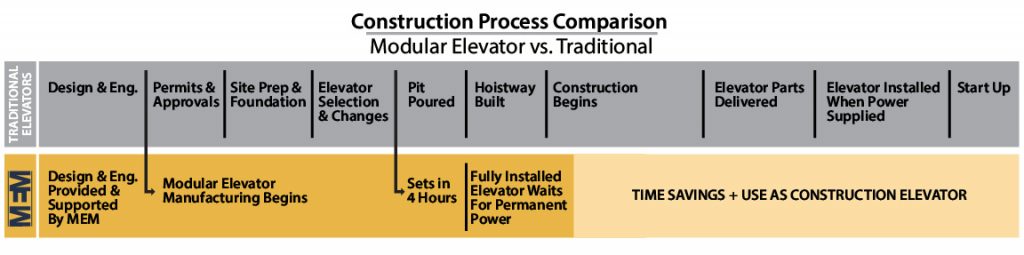

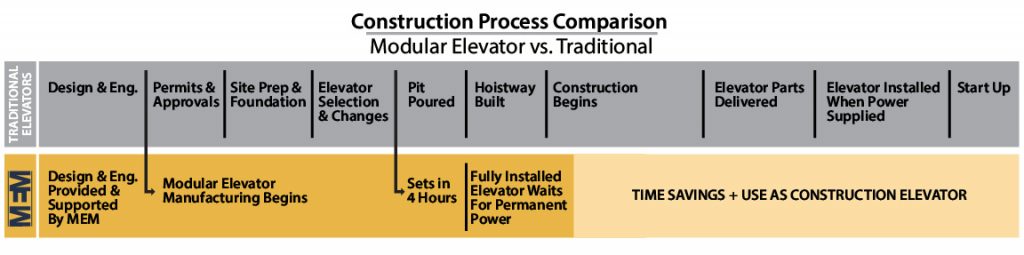

Then the elevator can be set in place, avoiding any possible delays. This also cuts the timeline for the entire project. You can see the difference in the chart below. Compare the timelines between the traditional elevator process in gray and the superior MEM elevator process in gold.

That means an overall savings, but most importantly it takes the elevator off the critical path giving you the freedom to choose when it will be set as a fully installed unit. Your elevator can be put in place in less than four hours.

The MEM elevator system also produces a higher-quality elevators due to the factory production. It allows for consistent quality control and inspections. The result is an improved process that is simply faster, greener and smarter.

Lastly, old-fashioned elevator companies haven’t changed their process since the Civil War no kidding! It is that outdated, dangerous and often causes costly construction delays.

Our system has been revolutionizing the elevator industry for over 20 years with a success rate of 100% and hundreds of units in operation. Now an educational facility, commercial property, medical facility, parking garage or housing unit can have a fully installed commercial quality elevator delivered when it is wanted. Anywhere you can put a traditional elevator, you can place an MEM.

As a result, if you are the least bit curious about our elevators and have a low to mid-rise project in mind, click the Fast Track button for a thumbnail budget number. Additionally, if you want to explore more, schedule a Live Virtual Tour of our facility. We will show you how we manufacture a high-quality elevator that sets in four hours and starts up in a week.

Elevator Placement. You have a low or mid-rise project ready for the design phase. One of the first considerations is elevator placement and location of the stairwells. Because this happens so early it is crucial to get right. As we all know making a changes later in the game can be extremely difficult and pricy. Often times the knee-jerk reaction is to plunk the elevator down in the design nearest the main entrance or center of the building. But, deeper thought is needed.

Especially with the surge in modular buildings, the hoistway and staircases are being used less often for structural support in many circumstances. That is not saying structural support by the shaft and stairwell is no longer needed. At the very least all hoistways should be able to handle some gravity loads associate with floor tie-ins.

Shear loads are something completely different and have to be accounted for in the structural design. But, mankind was designing successful buildings without using hoistways for support for hundreds of years before the advent of the elevator. So using the hoistway for that purpose is not always necessary, but the best option depending on design. Just keep in mind, especially in low and mid-rise applications the need for structural support (gravity or shear) may have to be examined before changes of elevator placement is made.

In addition to the structural aspects of the project, you should also consider where people are wanting to go inside the building. After all, if elevators are a matter of convenience and mobility, it makes sense to put the elevator where use is most convenient for the most people. Blending the two considerations of structure and traffic flow can be an art form! But where can you get started to determine placement?

So with all that said here is a list of considerations as to elevator placement:

The above is not a complete list of considerations. It is just a starting point to get you thinking more about the need and purpose of the elevator itself. Far too often in this copy and paste world, the largest and most expensive moving object in the building becomes a second thought. For more insights here is my cheat sheet for number of elevators per building that may help.

Remember the project architect and engineer are great resources to answer your questions. Even if placement is copied from previous jobs, there are reasons for where they put the elevator where they did. So ask early “why?” and if you have additional concerns express them. Nothing is worse than getting months into a project and then wanting a change. I have never met an architect or engineer that didn’t like explaining the reason they made a choice.

Lastly, an independent elevator consultant is a good idea if you have questions. They will examine all the aspects of the building from the perspective of an elevator expert. If you need help finding a consultant we will help you do so. We work with many of the best.

Also, our team can go through your concerns as well. Everyday we answer questions as the only elevator experts in the modular industry. To get the process started just click the button below. The Fast Track quote form will ask some simple questions to get us started, just fill out the info as best you can. You can also sign up for a live virtual tour of our facility. We will answer your questions about how we produce high-quality commercial elevators right in our factory, that gets shipped and placed in a few hours and started up in a week.

Another win for the team at Modular Elevator Manufacturing! An MEM school elevator was placed at Fred Kelly Stadium at El Modena High School for the Orange Unified School District. The completed stadium replacement was built by Byrom-Davey, Inc. With the architecture completed by – HED Architects.

It was great working with the school district who did a phenomenal job with the project, Byrom-Davey and HED Architects. This team was filled with professionals that truly cared about the end product and it shows!

Below are just some of the videos including the virtual grand opening that was held during the Covid pandemic. Great video, but we cant wait until the stadium is full with cheering fans this upcoming school year!

The video below shows the elevator at about the 23 second mark.

Additionally the video below is a virtual tour of the project. The MEM school elevator is highlighted at the 1:00 mark. The lit hoistway is impressive to say the least.

Also, a virtual grand opening below discusses the benefits of the elevator when talking about access at the 7:30 mark and it is show again at 19:15 when giving a tour of the press area.

Again, what an impressive team and fantastic completed project!

For more pictures of the project and the elevator we encourage you to go to Architect Magazine.

If you think you could benefit from a high-quality commercial elevator for your project that installs in just 4 hours, click the button below for a quote. Or, you can sign up for a live virtual tour to see how we create the easiest and fastest installing elevator in the business.

A free elevator is a dream for many. Let’s face it, elevators are generally expensive if you want a good one. However, if you sharpen your pencil and your perspective you can find vertical transportation that provides enough savings to make even the highest quality elevator significantly less expensive.

But, to start the hunt for a free elevator you have to begin with a question. What in real terms makes up a commercial quality elevator that you find in any building project?

Well, in most basic terms it has to have an elevator car, rails for the car to ride up and down on and a hoistway the rails are attached to. That skeleton then has to have a heart. The heart is the conveyance system that makes the car raise and lower as well as open and close the doors at each floor. After that, to carry the analogy further, it needs skin. A great looking interior to the car with lights, buttons, hall calls and handrails. The hoistway can also be part of the skin in the form of a glass elevator and decorative finish or just a painted surface. That is what an elevator is in its essence.

There are two processes to accomplish the above:

The differences in the finished product of the two elevators are negligible (other than quality) as most of the component come from the very same supplier companies regardless of the process. Whether you are buying a modular elevator or have an elevator installed onsite each has the same pieces or the components have been through the same rigorous approval process. These two systems produce generally the same elevator.

So if the products are largely the same and roughly the same cost, how do you get one for free with modular, but not traditional?

The answer is found in the savings that you can obtain because of the modular nature of the MEM elevator. The chart below explains the process for both. The traditional elevator is significantly different by the nature of how they are installed. They take much longer to cobble together on your jobsite when they want. There is design and engineering, followed by permits and approvals, site prep and the foundation and inevitable changes. Finally when the pit is poured and construction begins, the traditional elevator company lurches into motion.

They order parts and make sure logistically all the pieces and tools are dumped on your site with you contractually responsible. Then they start the installation process most usually after power is turned on.

MEM (the gold row) on the other hand arrives when you want. It takes the design and engineering that we have partnered together on and begins manufacturing. By the time the pit is poured the fully installed elevator is ready to be set in place. That takes about four hours (no kidding). As unbelievable as it may seem, you have a fully installed elevator sitting onsite waiting for power. Then when you are ready to have a fully functioning elevator turned on, we make sure it is started up properly. It is really that simple.

The traditional or old-fashioned way of putting in an elevator is at the end of the construction process. This throttles the completion and this is not idle speculation.

A thesis and study put forward by the Penn State College of Engineering supports this contention. In an actual parking garage construction sequence of a five-story project it was found that the elevators took a crazy 58 days to complete. Also, they were the last trade to get started other than landscaping and parking lot striping. They were also the last trade to finish. Now imagine changing that number of 58 days to ten, putting the elevators in first and using it as a construction lift like we did at San Jose State.

The date the parking garage opens comes sooner as the job closes faster. This reduces overall costs in addition to other benefits. No more making space for storage of all of the parts and pieces. Big sections of projects are cordoned off for this purpose. That slows the project. Not to mention all the coming and going with a big carbon footprint. Also they are burning your electricity to install the elevator. MEM’s elevator comes pre-installed.

Lastly, with a modular elevator once power is on and adjustments are made, you can use it as a construction elevator.

So now sharpen your pencil and put a dollar sign beside each item listed below. How much is it worth that:

As you can see with the above list and a sharp pencil you can save ten of thousands of dollars or more by using MEM elevators on every low and mid-rise project. The general conditions alone can run tens of thousands per month. So when you balance the costs and savings, you can have a higher-quality elevator installed when you want for less.

Is the elevator really free? Nope, but the savings you will gain using an MEM elevator will often be more than your investment. Not to mention the faster occupancy rate that has as an additional benefit. I was once thanked for trimming months off a project putting more money in the investor’s pocket on a hotel project.

So summing it all up isn’t it time to at least consider a modular elevator for your next project? To get the ball rolling all you have to do is click the Fast Track button below. The form asks a few easy questions and then we will contact you with an obligation-free budget number. If you want to do a little more research join a Live Virtual Tour of our facility to see how we produce the highest quality commercial elevator that installs in hours. Just click that button to get on the schedule.

| Thank you for Signing Up |