Non-proprietary parts matter. However, often times non-proprietary parts are over looked, not considered or just not understood. So, let’s start from the beginning. What’s the definition of non-proprietary elevator parts and how can they solve problems regarding your elevator choice.

Generally, proprietary elevator parts are components produced, marketed and controlled under exclusive legal rights of the manufacturer. The manufacturer has no obligation to share any information about the part or component, how it functions, how it operates, how it can be repaired or used to adjust or improve the overall functioning of an elevator unless it is contractually obligated to do so.

Non-proprietary on the other hand, means there are no restrictions to the use or what company can repair or improve the functionality of the elevator.

Well that was a mouthful. The definition can be reduced to a more simple, proprietary elevator parts are ones that only the manufacturer can repair or use in a repair or maintenance of an elevator. Non-proprietary opens the door to any qualified and licensed elevator professional.

An even more concise characterization is, proprietary bad; non-proprietary good.

But why? Why are proprietary parts to be avoided when looking at elevator purchases.

There are limited arguments against choosing an elevator that has non-proprietary parts over proprietary. When non-proprietary options were first available, there was a short time that they were considered inferior due to their recent emergence.

That thinking is no longer a concern. There is a decades long track record now that shows reliability and durability for non-proprietary components. Keep in mind that all elevator components and elevator operations are subject to elevator codes, inspections, and parts must pass rigorous testing before they would ever be allowed in an elevator.

Also, much of the functionality that proprietary elevators could boast of is now available with non-proprietary units.

Too many times we receive calls from individuals that are dissatisfied with their current maintenance supplier. They are sometimes unresponsive, operate at their own pace with little concern for the end user or the building owner and often lack availability of parts or tools with many on back order. With proprietary parts you lose the ability to find solutions to the problems you are facing.

This was illustrated in a recent article regarding elevator repair delays. A lack of parts was the cause for denying people mobility and access. You can help shorten that time of repair if you chose for your next project an elevator without proprietary parts. If you want to know more about us, just click one of the buttons below. We would love to talk to you about your next elevator project.

You should care – Elevator parts are not all equal…but they are. Years ago there used to be a commercial that had the catch phrase “Parts is parts”. They were talking about chicken nuggets and not vertical transportation and their facetious point was parts are not all equal. There are better and worse pieces of the chicken to use in the production of a nugget.

In the home or commercial elevator industry that knife cuts both ways and a bit hard to explain. First, it is true there are differences company to company in components. But second, those differences are superficial at best and for a purpose. So the parts are not all equal but… still equal??? How does that work?

That doesn’t seem to make sense so let me explain this weird dichotomy by stating the following. Factually, most companies purchase the bulk of their components from the same group of independent companies. As a result an elevator, home or commercial, is filled with dozens of components and pieces that come from those various companies from around the world. The difference is largely relegated to different nameplates and logos being etched or painted on the components themselves and that is about it.

This gives the illusion that they are all coming from the elevator company you are buying from. Generally that is not true. As a result when you step into an elevator car most often very little of what you see or that makes it go up and down, comes from the name on the control panel. And in all likelihood the bulk of those parts are found in every other elevator you ride regardless of the company.

Also, the vertical transportation industry, for good reason, is highly regulated. Elevators in the United States make 18 billion passenger trips per year according to the National Elevator Industry Inc. For that reason alone it is very important that all parts must meet high standards. You just can’t put anything you want in the elevator as a component. They must be test and approved for quality and durability.

Alright, if only a handful of companies produce most of elevator components and all parts meet the same rigorous standards, how can they possibly be different? Well before I get to that I want you to know that I am not wearing a tinfoil hat. I believe that we did go to the moon, Elvis is dead and aliens had no part in building the pyramids. So what I am about to say is not a crazy conspiracy.

Here, goes. The big commercial elevator companies make the bulk of their profits in maintenance and not selling you an elevator. Shocked? They realized pretty early on that if any certified elevator contractor could provide maintenance, they could lose customers and money. People would simply shop around and find the lowest price for service.

The solution was two-fold. First, sell elevators that require the most expensive maintenance agreements regardless of the purpose. Second, place in those elevators components from manufacturers that will require special tools, passwords or programs to maintain the elevator.

If you combine those two principles with a confiscatory maintenance agreement you have a lock on maintenance income for that unit for decades. And there is really no way for the building owner to extricate themselves from the long-term costs.

So, despite elevator components largely being the same, parts are not all equal. This is by design and for a specific purpose that has nothing to do with the elevator ride or functionality.

Unfortunately, when asked, “What can I do?” the responses are limited. This is especially if you already have an elevator in place. It is not practical nor cost effective to replace the proprietary parts that force you into the long-term contract. It’s like the old adage, you pay for some mistakes forever. But learning from those mistakes is important as well as spread the word that you can make upfront decisions next time that will save you from the headaches and costs associated with choosing the wrong company.

The word to commit to memory is non-proprietary. Non-proprietary parts and components are simply those that any elevator technician can work on. They are not better or worse they are just accessible for maintenance from any company. You can even use the big elevator companies if you wish. It just opens the door to anyone to repair or maintain the elevator. So always, always, always have an elevator installed with non-proprietary parts.

Finally if you have any questions regarding what proprietary parts and components can mean to your elevator project please contact us. At TL Shield and MEM we pride ourselves on giving honest answers to your questions about elevators, home or commercial.

All you have to do is click one of the buttons below to get started.

TL Shield is know in the Southern California area as the best provider of home elevators, wheelchair lifts and stair lifts. But many people do not know that TL Shield installs Modular Elevators as well. As vertical transportation experts with over 25 years of experience they have teams of quality technicians that are ready to install nearly any option that moves you up and down.

This was seen in their latest quality modular elevator installation at Newhart Middle School/Mission Viejo, CA. TL Shield installed an innovative modular elevator to perfection. As you can see, the project looks great. It went in faster for the school with no disruption to classes and embracing their movement towards innovation in what they teach and how they teach it.

If you would like to see more about this project or others like it, just let us know. We will meet with you regardless of what type of vertical transportation you need. We are experts that are willing to help. You can also schedule an in person visit by completing the form below.

For more great photos of the project, visit our good friends at Miller Construction. Their team did a great job as well!

Elevator 101 is about the basics. See, being around elevators all the time can warp your perspective. You begin to think that everyone has a pretty high base knowledge of elevators and elevator lingo. We tend to forget that most people’s knowledge of elevators in the construction industry is limited to, “They are a pain in the rear end”. So, every once in a while it is a good idea to review what the basic terms mean. Reviewing this info is especially needed if you are going to be chatting with people in the elevator business about a specific project.

Overall there is too much jargon. Like talking to a doctor or lawyer, elevator people sometimes skip over things that are basic to them, but may confuse folks not immersed in the field. The intricacies of brain surgery or the meaning of habeas corpus (I think its a city in Texas), can easily pass us by and so can terms regarding elevators. We hope this will help.

So here is a list of basic terms that you should review, or bookmark before you talk with an elevator consultant, elevator sales person or even an elevator mechanic.

That above list is a good staring point. However, if you ever have a question feel free to call us whether you have the intention of buying a modular elevator or not. As geeky and weird as it sounds, we like talking about elevators.

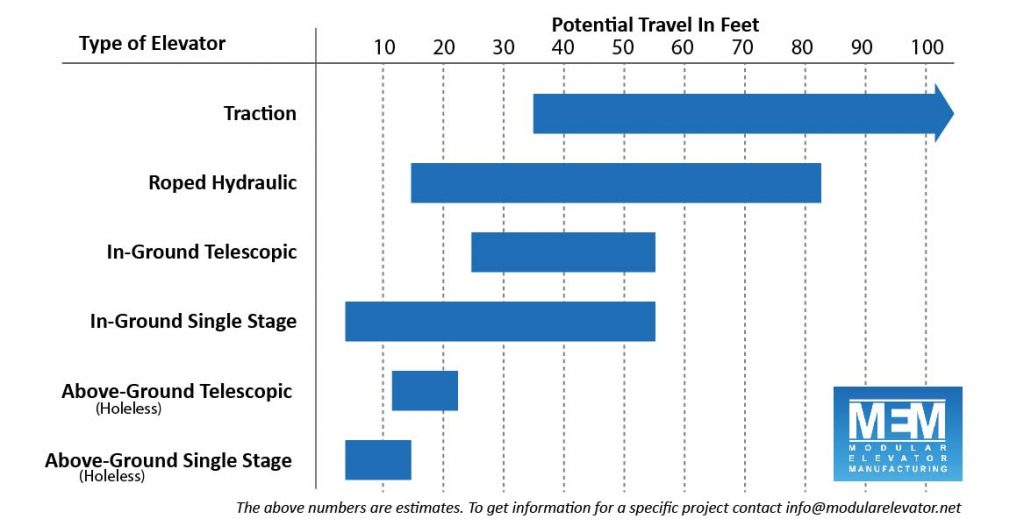

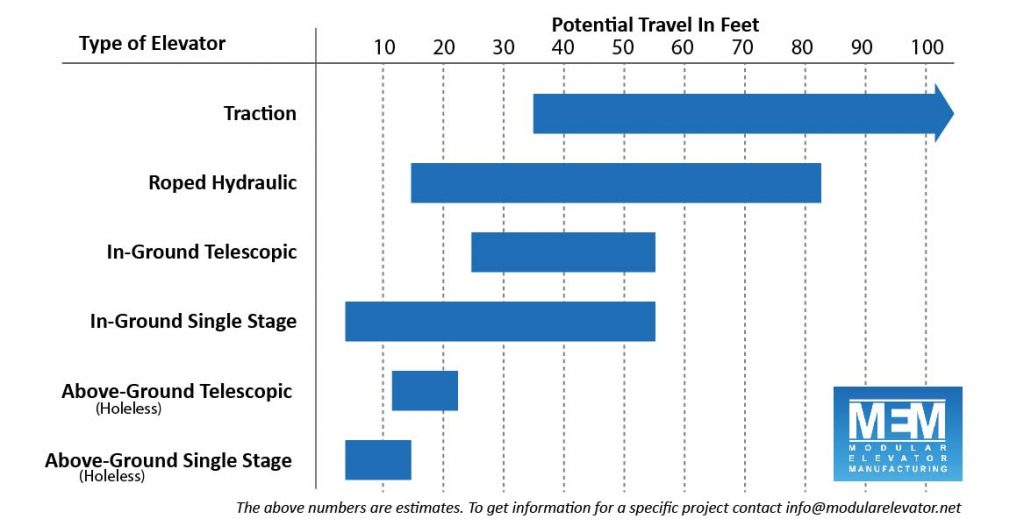

Below is a handy diagram, a chart based on travel distance and some links.

Additionally if you want to know more about the modes of conveyance. Just click here for a full explanation. You can also click here for information on hydraulic units. You can also look at the dozens of articles we have available on our blog.

If you would like to know a bit about pricing for a project just click the button below to get a Fast Track Quote. But if you really want to know more about elevators, schedule a live, virtual tour of our factory. It is open to anyone with questions about elevators. We love showing off!

I have been writing blogs forever. Not literally of course but, for a long, long time. And I have never gotten such an overwhelming response as I did writing the blog post Dirty Little Elevator Secrets. People that commented were upset with the old elevator industry and had their eyes open to the hidden agenda for the first time. They felt duped and manipulated in some cases. The result was I was asked to expand on the differences between a true manufactured elevator and what big elevator companies pass off as manufacturing.

So, that got me thinking, maybe I should expose more truths about a business that hides as best they can what they do and how they do it. And, if the audience demands it you roll out the sequel. I hope this will not be a Jaws 5 or Titanic 2 kind of effort. The goal is to be more of a Godfather-esque redux. Godfather 2 of course. Godfather 3 was a train wreck.

So, get your popcorn and super-sized drink. Here we go. Let me start by asking a simple question. When is an elevator manufacturer, not an elevator manufacturer? I know it sounds like the start of a children’s riddle, but the question is sincere.

The answer begins with telling you about what we do and who we are at Modular Elevator Manufacturing (MEM). We are a true elevator manufacturing company.

The process starts in our factory by building an elevator hoistway out of rugged steel tubing. It is engineered to be self-supporting and can meet any earthquake or hurricane standards. We then finish the shaft with mold resistant drywall inside and out. This gives it the fire protection required by the building code of the location it is going to. It also ensures the elevator can sit through the building process onsite.

The rails on which the elevator car will ride are then put placed inside. Always plumb and always level. The heavy lifting is relegated to machinery making the task easier and safer for employees. This entire time the hoistway is horizontally, whether for a low or mid-rise project. It remains that way throughout the process to assure perfect alignment and ease of inspection.

While the hoistway is being manufactured, the elevator cab is likewise being constructed. We use tough Galvanneal (stainless) steel and not flimsy wood core products that can easily mold, warp or crumble. It is built on a metal platform, with the sling. The cab is perfect in alignment, fit and finish as jigs and templates are used to assure all the manufacturing is within the strictest allowances.

The roof of the cab is completed with all the wiring and safety devises required by code. Then the interior of the cab is finished to meet the most demanding of specifications. Keep in mind that the cab is constructed on a factory floor with plenty of space to work around with easy access to every nook and cranny. The area is well lit and inspections can take place at anytime with easy access.

At the end of the two separate assembly processes, the hoistway and elevator cab are married together. The cab, platform and sling are simply inserted into the hoistway. The wiring to the hall calls is then completed. Keep in mind through the whole process inspections are done.

This is what a true manufactured elevator looks like. A hoistway with a completely finished commercial quality elevator installed inside. All that is needed is for the elevator to be set in place (a process that takes about four hours). And for it to be started up (a process that takes less than a week). The modular elevator usually goes in first in the building process and then completed when electricity is provided.

Now for what the old-fashioned, supposed elevator manufacturers do. They pull together boxes of components, parts and pieces from any number of companies and ship them to a job site. There they sit taking up space and getting in the way. Not only that, the construction team has to make space for the components as well as the mechanic’s tools and keep everything under lock and key by contract. If anything goes missing, it is not the elevator company’s fault but yours.

Finally, when the technician wants to get to your project they arrive. But don’t make the mistake in thinking they are going to start right in.

If it is a cold morning (under 55 degree in the shaft) they have to wait until it warms up. Because cold temperature can void the warranty they won’t lift a finger. The way they install the elevator requires that it is working in some fashion. Especially, in northern climates it is said that the elevator mechanic doesn’t watch the time clock, he watches the thermometer.

Then one piece at a time the maintenance person wanders back and forth from crate to shaft bringing in all the pieces, panels and paraphernalia. They then screw, cobble, coerce, bend and bolt all the parts together in the tight, cramped and poorly lit shaft. And you wonder why the elevator rattles like a teenagers jalopy when finished.

Elevator companies have little regard for the safety of workers because the technicians are required to do the lifting. Back-breaking labor is needed requiring the lugging around of heavy rails. No wonder that,

“The major causes of lost-time injuries to elevator installers and repairers were being struck by an object, overexertion (especially in lifting), falls, and being caught in/between, in that order.”

eLCOSH – Deaths and Injuries Involving Elevators

That being hit by an object is either by a piece being raised with a hoist in the tight confines of the shaft or someone dropping a part or tool.

All this is crazy. If they were truly manufactured in a factory setting it could all be avoided and the finished product would be much better.

Keep in mind that this installation and all of the pitfalls takes place last in the building process. So one misplaced bolt, one fried circuit board, one miscalculation or one injury can potentially delay the building for weeks to months. The rest of the project may be ready for occupancy, but the elevator brings everything to a halt. Also, if you raise any concerns or comments, you are viewed as the problem.

As they already have you over a barrel, more often than not you complain to co-workers or peers, but not to the elevator company. Fear of reprisals or slow-walking work looms in the back of your mind. But voicing your concerns wouldn’t matter anyway. You are stuck.

In the above scenario one company is a manufacturer…the other is not. I could be a little more forgiving if they actually manufactured all their own pieces and parts, but guess what??? Not so. They just bundle parts from a myriad of companies and ship them. They often use the very same companies we do for components. There is no real difference in the components used or the quality.

So if they in real terms are not elevator manufacturers, what exactly is their business model? How do they make money if they don’t really make the product they claim to? As a matter of fact, often times they sell their bundles of elevator components for little or no profit at all. At first blush you would say that’s crazy…until of course you look at what they do sell and how they sell it.

Otis in a recent SEC filing said, “New Equipment and Service, which, for the year ended December 31, 2019, contributed 43 percent and 57 percent of our net sales, and 20 percent and 80 percent of our total segment operating profit, respectively.” Most the money they are making regarding operating profit is in the maintenance agreement.

That is why they will sell new units for practically nothing, with proprietary parts and tools required in the product. That locks the builder, building owner or any future owner into a never ending contract. Often times the deal has clauses that guarantee annual increases and only short windows of opportunities to get out of the deal. When the jig is finally up you are locked in. And get this, even if you get out of one contract with the elevator company, you still have to have a maintenance company affiliated with the same brand. Only they have the proprietary tools for that unit.

You may be switching service providers but you will never leave the grasp of the elevator company once you ink the deal. It reminds me of the quote, “Just when I though I was out, they keep pulling me back in.” Michael Corleone – The Godfather: Part 3.

The character of Michael Corleone was in too deep and his choices were limited by his circumstances and very early choices made by his role. Ultimately, he is a truly tragic cinematic figure. Don’t be him. Don’t get in bed with a manufacturer who is not really a manufacturer and then realize it is too late regarding quality, building delays and unfair maintenance contracts.

They may have an offer you feel you can’t refuse, but look for better alternatives with the best elevator manufacturer in the business. MEM – quality elevators taking you to higher level.

To find out about alternatives click Fast Track button.

Elevator secrets mean more than you think, if you are in the process of buying an elevator for a building project. You need help! But despite pushing the help button none is to be found because there are dozens of dirty little elevator secrets the major elevator companies don’t want you to know about.

That should be no surprise, after all the elevator industry is more cloaked in darkness than the Illuminati or the New World Order. They tend to hide what they do and lurk in the fog regarding important items like: costs, timelines and motives. So, in this blog post I will shine some light on just two of the biggest elevator secrets. You will also be given tips on how to shed some much needed light yourself on an industry that desperately needs it.

But first, why do they hide the information? Let me tell you, it is not an evil plot devised by a cat stroking Bond villain. It is a more mundane motive. Money. If you, the consumer, are not given clear factual information, the likelihood is you will make poor decisions regarding vertical transportation. Also, you will become more reliant on the elevator company itself for the limited facts that are available. So your decisions will be made with few and skewed facts and that will ensure you bleed money and they get richer. The result is overall lifetime cost of an elevator becomes much higher than advertised. So let’s get started with just two elevator secrets.

The first of many elevator secrets is the real profit for the major elevator companies is based on keeping you under their thumb regarding a maintenance contract. Otis in a recent SEC filings said, “New Equipment and Service, which, for the year ended December 31, 2019, contributed 43 percent and 57 percent of our net sales, and 20 percent and 80 percent of our total segment operating profit, respectively.”

Did you get that? That means is that new equipment or elevator sales while important is no where near as profitable as the maintenance. And to keep the money rolling in, unknowing customers are being pushed into making decisions that increases the profit of the elevator company through the maintenance contract not the elevator itself. How do they do this?

The vast majority of people that ride in an elevator don’t give it a second thought. The doors opens, they walk in, push a button and go up. They do not care about the mechanical means of conveyance at all. But, selling up to a different type of elevator conveyance can make a bigger profit for elevator companies through the maintenance agreement. So…they push specific elevator types that increase the maintenance contract price. This is despite most riders or building owners not caring a wit about how they get from point A to point B.

So, when I personally speak to people that are being oversold on the type of conveyance it makes me a little steamed. Let me be blunt. If you are being sold a traction elevator (the kind with ropes) for a low-rise application you are most likely being oversold and more than likely being taken advantage of.

Why? Because the long-term maintenance contract for a 3-stop hydraulic elevator is around $200 per month (depending on where and other factors). For a 3-stop traction it can be $600 or more per month (depending on where and other factors). Need more convincing? Do the math. The lifespan of a typical elevator is 20 years (240 months). With hydraulic maintenance cost around $200 a month, that is $48,000 over the lifespan of the elevator. A traction elevator on the other hand, at $600 a month is approximately $144,000 over the lifetime.

Now you know why they upsell unwitting customers on traction when often it is not needed. They will even discount the initial sales price on traction units to make less upfront as a way to garner longer, more profitable returns. A real quick note, hydraulic elevators are not inferior just less expensive to maintain. Also, this is not a screed against traction units. Sometimes they are needed. We just honestly assess your project and make recommendations rather than selling you up to something you don’t need.

But that is not the end of the elevator secrets and profit motives. When the light bulb goes off and you realize you have been duped into overpaying and try to get out of the contract so you can competitively shop it, you can’t. That is because part of that cheap up front price usually includes proprietary parts in the elevator system. In simple terms, proprietary parts makes it impossible for anyone (other than the elevator company you bought it from) to maintain it. You are stuck. The elevator with proprietary parts requires special tools programmed for your specific elevator. There is no advantage to these tools at all they are just the keys to a prison you cannot escape from.

There are also lots of other contractual tricks of the trade to keep you locked in as well; like auto-renewals. Auto renewals are common place with almost everything now-a-days. Phone service to online entertainment auto-renews all the time. But elevator maintenance contracts often auto-renew with an annual increase built in and if you miss the tiny renewal window, you can’t get out. The contracts are often multi-year (usually 5 years) and are very lopsided in exclusions and other factors.

The second of the dirty little elevator secrets is the major elevator companies don’t really manufacture elevators at all, at least not in the way we generally think of manufacturing. They do produce some components, but in real terms they are bundlers of other companies parts and pieces. They crate them, ship them and screw them together on site, but the elevator is not manufactured at all, and the parts they actually make are limited. Believe it or not elevator companies have admitted that the real “manufacturing” takes place at the jobsite.

Think about it this way, if General Motors only crated up parts and dropped them off at your front door, you would not consider them to be a manufacturer. That would be a preposterous notion. Then in cold or heat, rain or snow, a mechanic would meander to your house at their leisure and cobble all those parts together in a process that takes months in your driveway. You would laugh out loud if cars were “manufactured” that way. Yet that is what is done regarding elevators.

This truth reveals a couple of realities. The elevators they sell are screwed together with very little supervision, inspection or quality control in dark and cramped environs and in all sorts of challenging conditions. Also, the safety and quality of the elevators rests in a single inspection at the end of the process when they are either given a green light or a punch list of code violations to fix. If that one inspector, in one visit misses something, they just do. Also, the code inspector is not necessarily looking for fit and finish, just functionality and code compliance.

Because traditional elevator companies just really gather elevator components from others, then anyone can buy those components and provide a better, truly manufactured solution. That’s what happens with a modular elevator. We purchase the same or comparable parts, and actually manufacture an elevator in a factory. It is much faster, greener and safer.

Inside a modular unit you will find the same parts because there are precious few elevator component producers. Where different parts are used, due to the level of regulation in the elevator industry, they are all high-quality. All must pass muster of regulating agencies and the elevator code. We just produce the product in a much better and smarter way.

What ultimately makes the difference is that modular elevators are actually manufactured in an assembly process. They are not pieced together in less than optimal working conditions. Imagine that! They are inspected daily for fit and finish. They are always plumb and square because checking quality is as easy as walking the factory floor. The units are produced horizontally so inspections are routine and daily.

Also, because it is manufactured you decide when it arrives. It is then shipped and is placed on-site. This ends workplace interruptions and the elevator is no longer holding up other’s work. They free up work space and the elevator is off the project’s critical path.

The set is less than a half a day. The startup less than a week. And get this, the elevator can be used for construction in some cases! A better elevator because the process is better. Same quality components, manufactured smarter.

Below is an honest list of things to look out for on your next elevator purchase. However, it is a bit self-serving. We feel MEM is the best alternative for quality, safety and cost-effective vertical transportation. However, your decision must be made based on facts and below are some to consider. So, look over this info to avoid some of the dirty little elevator secrets and feel free to challenge us with questions about our process and products:

Finally, consult, challenge and discuss. Biased? We are. But not regarding the conveyance type. We will be honest and fair. On our factory floor you will find hydraulic elevators and even roped hydraulic units as well to meet your needs. Our bias is based upon modular being a better way to produce elevators, not the elevator itself. We will recommend what you need and price anything else you want or have speced in.

If you are curious and would like more information just click the button below. In 24 hours we can produce a thumbnail price for any project. Remember with us there are no secrets! Just straight forward talk from people that care about you and your project that are highly experienced in the elevator industry.

Elevator installers and technicians need to know more than how to turn a wrench. As you all know, Modular Elevator Manufacturing (MEM) is now nationwide, so we are looking for the right kind of knowledgeable people with the desire for growth. We are lining up work across the United States and in Canada and it is opening up opportunities for businesses and individuals in the elevator industry.

There are two ways you can be a part of the ever-growing field of modular elevators:

It starts with filling out this simple questionnaire. We just need to know you are a licensed elevator technician, the jurisdictions you work in and your contact information. From there we will speak to you about any future opportunities.

As an overview, we will provide you with information you need to setup and startup an MEM product. We will also help you with knowing your time commitment to any project you bid and give you in person support as needed. Note we do not say install the elevator, but setup and start up. This is due to the traditional elevator installation takes place in the factory. The hoistway is completely wired, with doors, rails and even the cab installed when it arrives. That means there is significantly less time invested in each project. For a quick look at how fast a set can go, click the button below. Generally a fully installed elevator can be set in a couple hours.

Most importantly know that we are looking for a long-term relationship that we can build on together. We have a solid, high-quality product, unlike other modular elevator companies. The result is we are looking for solid, high-quality people to join with us.

As you understand, there can be a significant lag time between the quote and getting the job. But you will won’t have the future opportunity if you don’t get start today.

Go to this page for more information and for general expectations. If you already know of a project that might be a good fit, let us know by clicking the Fast Track Button below. We will supply you with pricing in 24 hours so you can provide it to your potential customer. Otherwise click below and fill out the simple application today.

For years Modular Elevator Manufacturing has been educating the public on elevators in general and the benefits of hydraulic elevators specifically. Hydraulic elevators are often times the absolutely best option for vertical travel, especially when it comes to low-rise applications. However, we have not spent an inordinate amount of time discussing many of the drawbacks. That is because there are very few and generally well understood. However, it has come to our attention that some of these drawback have taken on a life of their own and now live on in near mythic proportions.

So in this short article we are going to address the ups and downs of the hydraulic elevator, dispel myths and shed some light. This is not a sales pitch! After all you can buy a high-quality, commercial hydraulic elevator from any number of companies. We look at this article as a help to those that are truly curious about the best elevator for their current or future elevator project.

To keep me organized and to keep from jumping all over the place, I will address each point listed below. These are the largest complaints that many have about hydraulic elevators:

Believe it or not, there is merit to some of the claims made above, but the explanations are often ignored and this has led to more than one exaggeration. That begs the question, why would one perpetuate a misleading claim? I hate to say it, but sales and profit motives are usually big factors. If more money can be made, why sweat the small things like the truth and developing a reputation over time. After all, the elevator industry has such a stellar reputation, why damage it for a few dollars? Just kidding on the reputation crack. One of the biggest battles we face as an elevator manufacturer is the overall reputation of the industry as a whole.

Ask nearly any general contractor, building owner or architect and they will affirm they dislike the elevator business. In my experience and when doing independent research I have personally heard elevator companies described as bullies, untruthful, unreliable, unresponsive and overpriced. Do any of those descriptive terms surprise you? Unfortunately, probably not. So let’s just say that profit motives are powerful and can lead to some generalizations and exaggerations. But more than that, in the late 1990’s a new product was introduced to the American market. The MRL (machine room-less) traction elevator was rolled out with tons of fanfare and major investment from big elevator companies.

Logically, for that investment to payoff significant downward pressure was applied to sell up MRLs. Incentives were created, promises were made and poor comparisons were projected. Those sometimes false comparisons still ruminate in the minds of many. This coupled with ignoring hydraulic elevator technological improvements leads to a misunderstanding of facts and benefits. But let’s get to the list.

The first common complaint is that hydraulic elevators cost too much. Not necessarily in the upfront investment in installation, but in the Life Cycle Cost or LCC. The initial cost of a hydraulic unit runs around 35% less that a traction MRL. Not only is that true of pricing at Modular Elevator Manufacturing, but across the board, but what about maintenance and electricity? How does hydraulic stack up against MRL traction?

This question was answered by a study from of all places Thyssenkrupp. They were so interested in this question that they commissioned a report and then published its findings in a blog. The answer may surprise you. They found the following:

“We conducted Life Cycle Costing (LCC) research on low-rise elevators to help customers understand their economic and environmental impacts. LCC looks at the costs involved with a product or service over its entire lifetime. The study showed that over 25 years, the cost to maintain three-stop traction MRL is $173k compared to the same hydraulic MRL which cost $91k.”

Myths about Low-Rise Elevators Means Realistic Costs to Building Owners – Tetley-Scott 2014

Keep in mind that is the cost to maintain the elevator, not buying it and install it as well. That is a stunning admission. They are in basic terms saying that an MRL traction is, give or take, seven grand out of your pocket every year when a hydraulic is only three thousand-seven hundred. That is for the same travel distance and same number of stops. Cost wise hydraulic is the only logical choice. This is especially true when you add in the initial investment cost.

Regarding electricity, the same blog post points out, “In fact, a 2,500 lb. elevator, traveling a single floor (12 feet) at 100 fpm (feet per minute) and operates 100 runs a day, does not even use $600 worth of energy in an entire year. So assuming the hydraulic uses more energy than traction, you could have a differential of perhaps just $150 a year in energy cost.” In other words, in the whole picture, although a hydraulic elevator may use more electricity in a year, it is negligible to say the least.

It is an old canard that hydraulic elevators use significantly more energy than a traction. If it were true, we would produce counter-weighted hydraulic systems. It would be easy enough to do, but who on earth would pay so much up front and then have a more additional maintenance costs of weights and ropes? They make no sense because the electric cost is so low and going down every year as efficiency in hydraulic pumps and motors increase.

This is no old myth. When hydraulic elevator were first installed there were a couple of factors that made them less green than their traction counterparts. The hydraulic fluid used was not bio-degradable and the oil was in a jack underground where leaking could not be effectively monitored. It was a time bomb of sorts as rust and corrosion slowly wore away at the hole lining, jack and bulkhead. The seals were more prone to failure and the drips turned into steady streams of lost fluid.

There are still hundreds of these old systems in place today. And they are either, by some miracle leak free, they are not being routinely checked for oil loss or the person paying the bills would rather buy a five-gallon bucket of oil every quarter than have the jack pulled and replaced.

But things have changed. In many applications you can use above ground jacks and better materials are available when an in ground jack is needed. Generally, PVC filled with sand is in the hole and then the jack is inside the PVC. If installed properly there should be no leaking at all.

Also, the elevator code has recognized the need for improved environmental awareness. If the code is followed, environmental issues should be non-existent to rare. If there are any problems or accidents of an environmental nature it is more than likely due to unqualified installers. Current technology affords jack leak monitoring systems and all the jack components are better than in years past. This coupled with good maintenance and record keeping should significantly reduce any hydraulic fluid escaping into the ground.

But what if it does? Good question. The last line of defense are interceptors for spilled oil that separate the oil from water protecting the environment against leakage. And also you now have the choice of many bio-degradable hydraulic fluids formulated for elevators. Oil replacement and additional testing is necessary so the elevator technician needs to know of this choice. But there is no real need to worry about leaks if you don’t want to with improved rules and technology.

Okay hydraulic elevators are slower. But does that matter? I really could write an entire article on this subject…as a matter of fact I already have. You can check it out here. You can read it if you are really interested, but for everyone else let me cut the the chase. Speed is really needed if you are going over six or seven stories for sure and maybe a wanted convenience you would like going over four or five stories. But for anything below that you are not getting your money’s worth.

The reason is due to limits of the human body and how fast an elevator can get to top speed and still be a comfortable ride. If you are traveling just 30 or so feet you would just barely get to top speed before starting to slow down again for the next stop. Top speed is rarely to never hit in a typical three stop elevator. Think about it, you would be thrown to the floor or pasted to the ceiling if you traveled to top speed any faster. So yes, hydraulic elevators are slower, but for low-rise applications it is not that important at all. Yet everyday we send out Fast Track budget numbers to people that are convinced they need a jet pack for 10′ to 20′ feet of travel. The need for that much speed does not exist.

To increase speed at a lower cost a roped hydraulic is a great option if you are going over three or four stories. It combines a hydraulic system with a pulley wheel at the top of the jack. This speeds up the elevator and increases the total height of travel.

Although limited, hydraulic elevators may go higher than you thought. Two or three stops are just the beginning. I have seen hydraulic elevators installed up to six stops. That is with over 60′ of travel! The chart below shows a comparison of what MEM can provide and associated travel. Keep in mind these are only general numbers.

The important thing is to weigh all the options available and not make any snap decisions without some research. For building owners and managers, that may mean asking some hard questions of your team and comparing costs to benefits. For the architect it may mean thinking outside of the elevator cab. Look for a better technology, before you drop in the same footprint. For the GC you might need to call and ask questions about how other alternatives can make your job easier, not harder when it comes to the elevator installation.

It is important that, when looking at the elevator alternatives, you do not just listen to sales pitches. Doing so will cost you significantly more in both the short and long term. I hope this article makes clear that traction elevators are not a proper alternative for two and three stop projects accept under certain circumstances. Also, hydraulic elevators up to five stories need to be considered. Based on cost and use you may find a hydraulic as the best alternative. Just take a look at the facts, determine your needs, and choose wisely.

You will be keeping your elevator for a long time so seek independent voices. MEM can be a great resource or a qualified elevator consultant. We won’t say one is better than the rest just for a sale. Just find the proper and most applicable mode-of-conveyance for the right application.

If you have a project in mind, or questions about this article or our line of manufactured elevators feel free to contact us for Fast Track budget numbers. Our knowledgeable team will happily advise you on the most effective and beneficial mode-of-conveyance for you and your project. We can provide budgetary numbers in 24 hours.

Elevator Babies – It was hard to resist putting a photo of my 6 month-old granddaughter in this article, but I didn’t because that would be way too much bragging and she is too young to be internet famous…at least among our 20,000 readers. But while holding her in my arms I got to thinking about how wonderful being a newborn is. No responsibilities; cry you get food; cry you get changed. Babies get to enjoy a short period in their life when knowing nothing is part of the job description and it is adorable. Sleep, eat, and be held is pretty much the day in a nutshell.

When it comes to the elevator business however, being a neophyte is far from wonderful or adorable. Elevators, need I remind people, are serious. They are costly, have thousands of parts and if they are improperly built they can be dangerous to the riding public. They are the largest and most complex moving component of a building. Knowing nothing about elevators or being elevator babies, but then selling them anyway is not cute or adorable; it is a hazard that can cost time, money and potentially cause injuries. But, that is exactly what you can get if you choose to call the wrong elevator company for a bid or project.

Modular elevators are just the same as stick-built in that regard, especially when you are talking about time and money. We all know that modular building is a wave that has already crashed the old-fashioned way of doing business’ party. It is the best option for any mid-rise building needing vertical transportation and will continue to be in the future. They are simply faster and better. But, if you are not careful, there might be an amateur on the other end of the phone line, selling you up and guessing at rules and regulations. After all when you call a modular elevator company you expect they are the experts in not only modular buildings, but elevators as well, but that is simply not the case if you call the wrong one.

One of the modular companies in particular out there that sells a cheap variety of modular elevator purports to be elevator experts. They are far from it and when you know the facts it can be a bit scary trusting a sales team that has no real experience. When I say no, I mean no. Three out of four of the sales team has a combined total of elevator or modular experience of less than a year. Yes, I said combined. My granddaughter has more experience being a baby than they do individually when it comes to elevators or modular units.

But it doesn’t stop there. The Quality Control Manager and Production Manager had no experience in modular building or elevators before coming to that company. Think about that for a second. The person that is supposed to be checking on quality has never checked for quality in the elevator business. In other words, watch out! Beware! Someone selling you an expensive piece of equipment and checks for quality and production that has a direct impact on your construction timeline has little knowledge beyond pushing the up or down button.

The person you are speaking to on the phone is not who you think it is when it comes to real world experience. They maybe elevator babies!

The good news is that there is an alternative to going to the nursery for elevator and modular advice and information. This is important to know as modular elevators are the future of construction.

MEM (Modular Elevator Manufacturing) is that knowledgeable alternative that has been producing elevators longer than any current modular elevator company and measures their experience in decades, not months. They have been there, done that time and time again when it comes to construction, modular building and elevators.

If you have gotten a quote from another company…give them a call before it is too late or if you have any questions about the benefits of modular elevators or how modular can make your life easier, I would recommend that you contact Hugo Beltran hbeltran@tlshield.com at MEM. You can also get started on your project by clicking Fast Track Quote. They are a company with experience that can give an honest, fair assessment of your needs.

Babies, especially my granddaughter, should be in the arms of someone that loves them, not on the phone dolling out sage advice about elevators like they are all wise through experience that does not exist.

| Thank you for Signing Up |